ENVIROFLEX

Used Oil Treatment and Re-refining Technologies

Enviroflex Altöltechnik GmbH is a leading provider of turnkey solutions for the re-refining of used motor and industrial lubricants. Our advanced systems include:

- •Water and light fuel separation by Distillation Towers

- •Multi-stage Wiped Film or Short Path Evaporation under high vacuum (up to 0.1 mbar a)

- •Final decolorization and purification using reactivable Activated Bauxite Polishing Units by reactivable Activated Bauxite (TURBOSORB)

- •We are one of the few companies manufacturing oil polishing units for both black base oils (POLISHLUBE) and transformer oils (REGENX), using reactivable bauxite that can be regenerated hundreds of times. We also supply mixed and formulated Adsorbents for various applications.

Enviroflex Group is certified according to ISO 9001:2015 and HSE-MS standards. All our equipment is manufactured in compliance with CE regulations and relevant European safety and quality standards.

Products

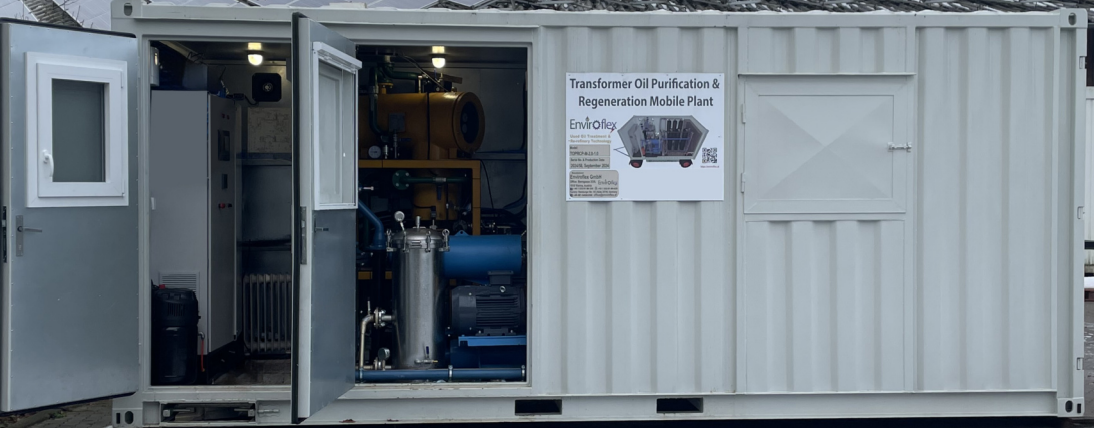

Transformer Oil Purification & Regeneration Plant ReGenX/RePureX – Stationary or Mobile

(Other applications – Base oil upgrade, Hydraulic oil regeneration, Diesel treatment, Paraffin decolorization)

Purification:

- •Capacity – 500…12000 l/h

- •Off-line / In-line versions

- •Water, combustible gas & air, particulate matter and dirt removal

- •Tan Delta & Dielectric Strength improvement

Regeneration

- •Regeneration of aged transformer oil to new condition according to IEC60422 & IEC60269

- •Reducing Power Factor and gassing tendency

- •Removal & Reduction of Silicon, Acidity, Sulfur odor & Color content

- •Interfacial Tension & Oxidation stability

Purification & regeneration plants can be delivered alone or combined.

Used Lubricant RE-refinery ReLubeX

- •Production of Base Lube Oil & Distilled Fuel from used motor oil & used lubricants

- •Base Oil with API Group II

- •Extracting light fuel and heavy distilled fuel (Diesel)

- •Heavy hydrocarbon Residue used at Asphalts Factories

- •Evaporation/Distillation process under low & high vacuum by Vacuum distillation Towers & Short-path Evaporators

- •Different Base Oil viscosities by vacuum setting and several distillations Maximum base lube oil recovery up to 82%

- •High Vacuum Pressure, up to 0.3 mbar a

- •Low evaporation temperature, Max. 310° C (preventing any cracking)

- •Polishing/ Decolorization by Activated Sorbent

- •Sorbent Reactivation hundreds of times

- •Different plant feed amount Capacities, 1 ton/day up to 100 ton/day

- •Product without any bad smell, Stable product, no color degradation, no emission, usage of chemical scrubber, and activated carbon filter for preventing any air pollution

- •Short investment payback period (1-3 years)

Other products

Combined Belt Filter Press & Belt Thickener for municipal and industrial Sludge Dewatering

Composting plants and accessories

Additional Documentation

Contact us for ENVIROFLEX solutions

For more information about ENVIROFLEX Valves products and their applications, please contact our technical team. We can provide you with comprehensive product documentation, technical specifications, and customized solutions based on your specific requirements.